Heat Treated Grader Blades Manufacturer in Patna

Heat Treated Grader Blades are blades that are treated with heat so that the cutting edges of the blade become harder and can last longer. This treatment makes the blade resistant to wear and tear, which prolongs its lifespan.

How are Heat Treated Grader Blades Made?

Grader blade is a very important machine part in the production of various types of products. It is used to smooth and shape the product. Grader blade is made from special steel that can withstand high temperatures while working. Here, we will tell you how these blades are made and treated so that they can meet the required standards.

The manufacturing process of a heat-treated grader blade starts with applying heat to the desired area on the blade. The temperature should be high enough so that the metal reaches its austenitic phase (a form of steel where it retains its Crystal structure). After being heated, the metal is then quenched in water or oil to stop the expansion of the metal and restore its original shape. This treatment makes sure that the grader blade can withstand high temperatures and keep its sharpness for a long time.

Are Heat Treated Grader Blades Safe for Use?

There is a lot of confusion about the safety of heat-treated grader blades. Some people believe that they are inherently dangerous, while others claim that they are just as safe as conventional blades. In this article, we will look at the risks and benefits associated with using heat-treated blades, and provide a verdict on their safety for use in a workshop.

The main concern surrounding heat-treated blades is their ability to resist wear and tear. This means that they can last longer than conventional blades, but it also means that they are more likely to cause injury if they break. One study found that heat-treated blades were more likely to cause joint damage than conventional blades. However, there is no evidence to suggest that these injuries are any worse than those caused by conventional blades.

On the other hand, there are some benefits to using heat-treated blades. For example, they tend to be less brittle, which means that they can handle higher levels of stress without breaking. They also have a higher degree of hardness, meaning that they can cut harder materials without wearing down quickly. Overall, the jury is still out on whether or not heat-treated blade are safe for use in a workshop. While there is evidence to suggest that they may be more prone to causing injury, this does not mean that they are automatically dangerous- it simply means that users should take caution when using them.

Benefits of Using Heat-Treated Grader Blades

There are many benefits of using heat-treated grader blades in your business. The blades will last longer, be more efficient, and reduce the amount of wear and tear on your machine. They also offer a higher level of precision when grading products. Finally, they are less likely to create sparks that can cause fires.

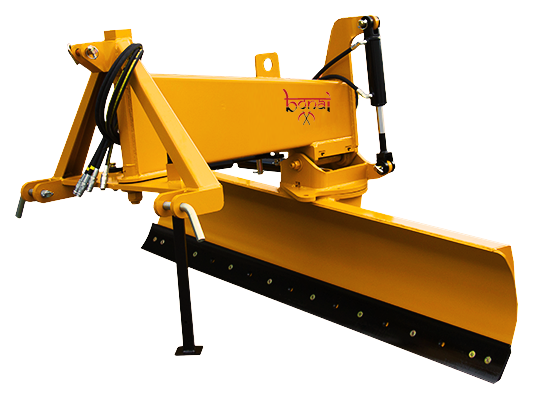

Bonai India XCMG Grader Blades Manufacturer

The Bonai India is XCMG Grader Blades Manufacturer that produces blades that are specifically designed for use with XCMG machines. The blades are made from high-quality, durable materials and are designed to provide excellent results in terms of accuracy and productivity.